Maintenance Discovery

Maintenance discovery involves the process of identifying, analyzing, and implementing improvements in maintenance practices to enhance the reliability, efficiency, and cost-effectiveness of equipment and facilities

Maintenance Discovery Overview

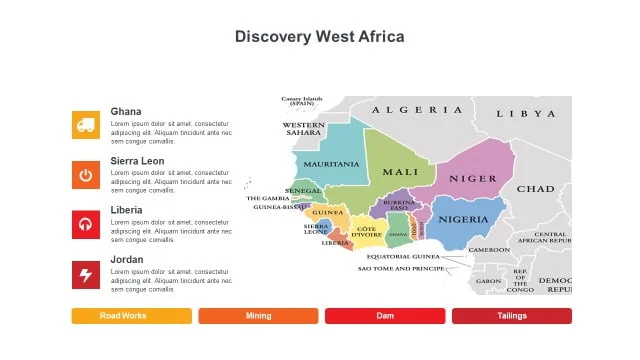

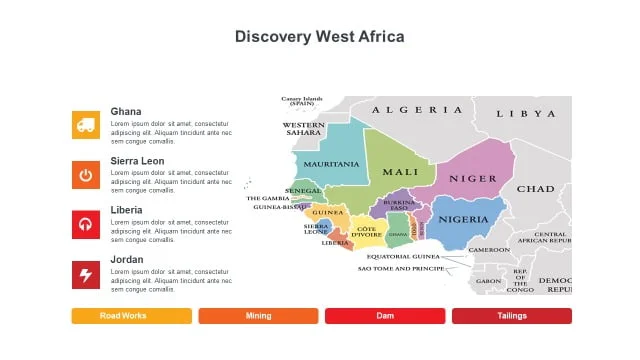

Mining discovery often begins with geological surveys and exploration activities to identify areas with potential mineral deposits. This can involve satellite imagery, aerial surveys, geological mapping, and geophysical prospecting techniques such as seismic surveys, electromagnetic surveys, and gravity surveys

Once potential sites are identified, exploratory drilling is conducted to extract core samples from the ground. These core samples are analyzed to determine the presence and concentration of minerals, as well as the geological characteristics of the deposit

Geologists and mining engineers analyze the composition of the core samples to identify the types of minerals present and assess their economic viability. This may involve laboratory testing, mineralogical analysis, and chemical assays to determine the grade, quality, and quantity of the mineral deposits

Based on the data collected from exploration and drilling activities, resource estimation is carried out to estimate the size, shape, and distribution of the mineral deposit. This involves geological modeling and statistical analysis to calculate the mineral resources and reserves

Once the mineral deposit is delineated, feasibility studies are conducted to assess the technical, economic, and environmental viability of mining operations. This includes evaluating factors such as ore grades, mining methods, processing techniques, infrastructure requirements, environmental impact, and market demand

If the feasibility studies are favorable, the mining project moves into the development and production phase. This involves securing permits, acquiring land rights, constructing mining facilities, and implementing mining operations to extract and process the mineral ore

Mining companies often continue exploration activities even after a deposit is discovered and production begins. This is done to expand reserves, optimize mining operations, and identify new opportunities for resource extraction

Advances in mining technology, such as remote sensing, automated drilling, and data analytics, play a crucial role in improving exploration and discovery efforts, enhancing efficiency, and reducing environmental impact in the mining industry

Mining Discovery

Mining discovery typically refers to the process of identifying and locating valuable mineral deposits or resources beneath the Earth’s surface

Mining Discovery Overview

Maintenance discovery often begins with the implementation of condition monitoring techniques to assess the health and performance of equipment in real-time. This can include vibration analysis, thermal imaging, oil analysis, ultrasonic testing, and other predictive maintenance methods to detect early signs of equipment degradation or failure.

When equipment failures occur, maintenance teams conduct root cause analysis to determine the underlying reasons and contributing factors. This involves investigating equipment histories, conducting failure mode and effects analysis (FMEA), and using other problem-solving tools to identify the root causes of failures and inefficiencies.

Maintenance discovery leverages data analytics and machine learning algorithms to analyze large volumes of maintenance data, equipment performance metrics, and operational parameters. This helps identify patterns, trends, and correlations that can provide insights into potential improvement opportunities and optimization strategies.

Reliability engineering principles are applied to assess the reliability, availability, and maintainability (RAM) of equipment and systems. This involves analyzing failure data, calculating reliability metrics such as mean time between failures (MTBF) and mean time to repair (MTTR), and identifying areas for improvement to enhance overall system reliability.

Maintenance discovery considers the total lifecycle cost of equipment and facilities, including acquisition, operation, maintenance, and disposal costs. By conducting lifecycle cost analysis, maintenance teams can evaluate different maintenance strategies, prioritize investments, and make data-driven decisions to optimize asset performance and minimize total cost of ownership

Maintenance discovery is an ongoing process of continuous improvement, where maintenance practices are continually evaluated and refined based on feedback, performance metrics, and lessons learned from past experiences. This involves fostering a culture of innovation, collaboration, and learning within the maintenance organization to drive sustainable improvements over time.

Advancements in maintenance technologies, such as predictive analytics, Internet of Things (IoT) sensors, digital twins, and computerized maintenance management systems (CMMS), play a crucial role in enabling maintenance discovery initiatives. By adopting these technologies, organizations can streamline maintenance processes, automate routine tasks, and gain real-time insights into asset health and performance.